Train a Segmenter

This guide shows you how to set up and configure the OV20i segmentation feature to automatically detect, measure, and analyze specific features or defects in your parts. Use segmentation when you need to identify irregular shapes, measure areas, or detect specific patterns that can't be handled by simple classification.

When to Use Segmentation: Surface defects, fluid spills, irregular shapes, area measurements, pattern detection, or any features where pixel-level precision is required.

Before You Start

What You'll Need

- OV20i camera system set up and connected

- Test parts with features you want to segment (e.g., sheets with pencil marks)

- Good lighting conditions for your specific application

- 15-20 sample images for training

Step 1: Create a Segmentation Recipe

1.1 Start New Recipe

- Navigate to All Recipes page

- Click

+ New Recipe(top-right corner) - Enter Recipe Name: Use descriptive name like "Pencil_Mark_Detection" or "Surface_Defect_Segmentation"

- Select Recipe Type: Choose "Segmentation" from dropdown

- Click

OKto create

1.2 Activate Recipe

- Find your recipe in the list (shows as "Inactive")

- Click

Actions > Activate - Click

Activateto confirm

✅ Result: Recipe is now active and ready for configuration.

Step 2: Access Recipe Editor

- Click

Editnext to your active recipe - Click

Open Editorto confirm

You'll now see the Recipe Editor with segmentation-specific options.

Step 3: Configure Camera Settings

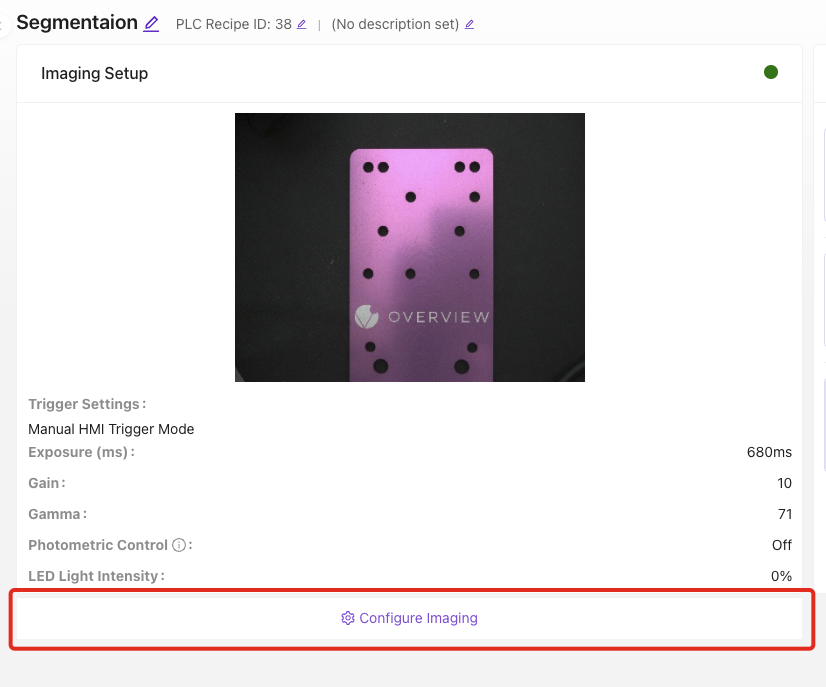

3.1 Open Imaging Configuration

- Click

Configure Imaging(lower left-hand side)

3.2 Optimize Focus for Segmentation

Focus is critical for accurate edge detection:

- Position your test part in the camera view

- Adjust Focus until edges are sharp and clear

- Test with different parts to ensure consistent focus across your range

- Focus on the surface where defects/features will appear

- Ensure the entire area of interest is in sharp focus

- Slight over-sharpening is better than soft focus for segmentation

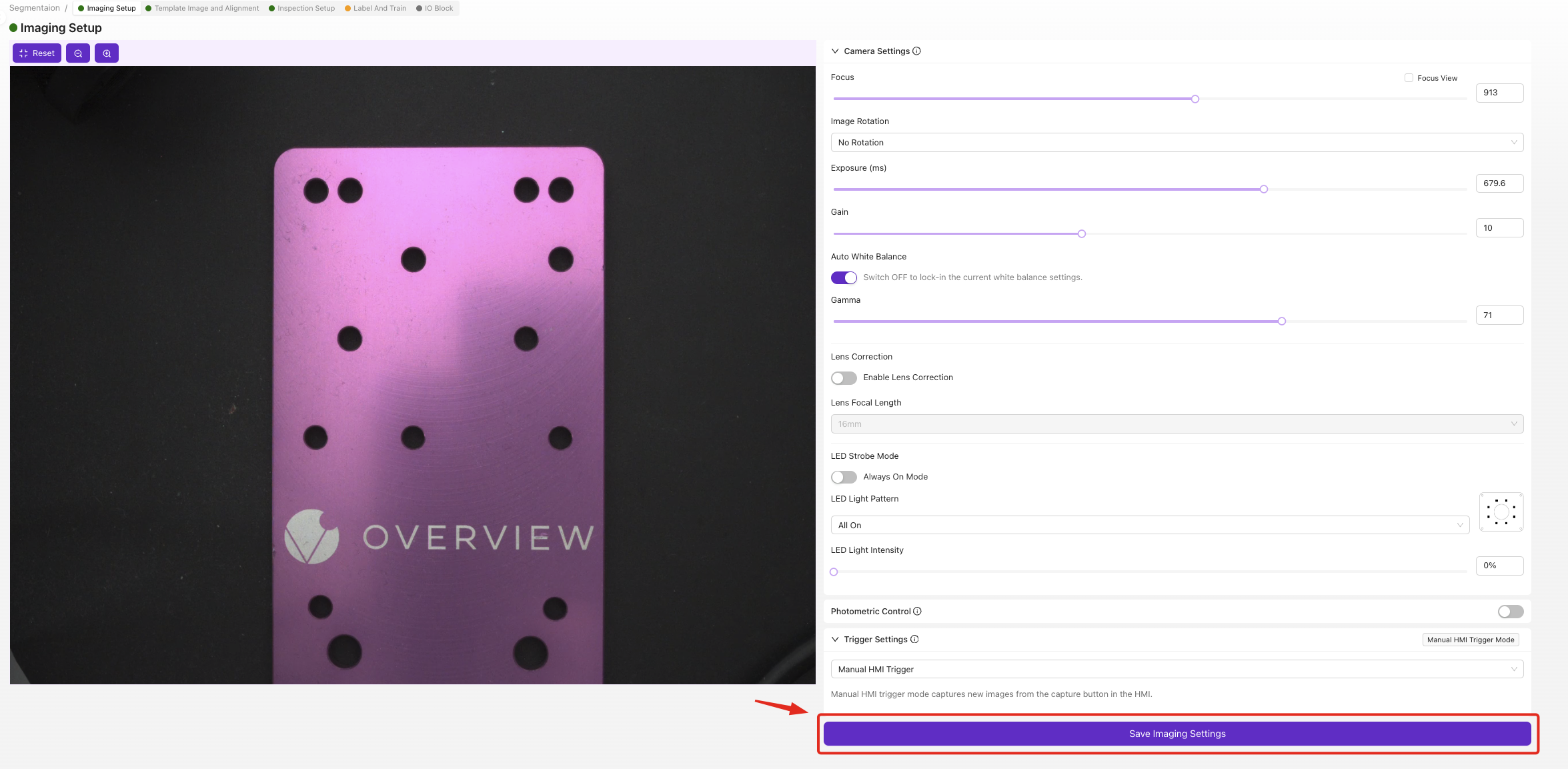

3.3 Set Optimal Exposure

Proper exposure ensures consistent feature detection:

- Adjust Exposure for balanced lighting

- Avoid overexposed areas (pure white regions)

- Ensure features are visible with good contrast

Segmentation Exposure Guidelines:

- Features should have clear contrast with background

- Avoid shadows that could be mistaken for defects

- Test with various part conditions (clean, dirty, worn)

3.4 Configure LED Lighting Pattern

Choose lighting based on what you're segmenting:

| Feature Type | Recommended Lighting | Why |

|---|---|---|

| Surface defects | Bright field | Even illumination shows surface irregularities |

| Scratches/cracks | Side lighting | Creates shadows that highlight linear defects |

| Raised features | Dark field | Makes raised areas stand out from background |

| Liquid spills | Side lighting | Shows surface texture differences |

3.5 Adjust Gamma for Feature Enhancement

- Increase Gamma to enhance contrast between features and background

- Test different values while viewing your target features

- Find setting that makes features most distinguishable

3.6 Save Configuration

- Review settings in live preview

- Click

Save Imaging Settings

✅ Checkpoint: Features should be clearly visible with good contrast.

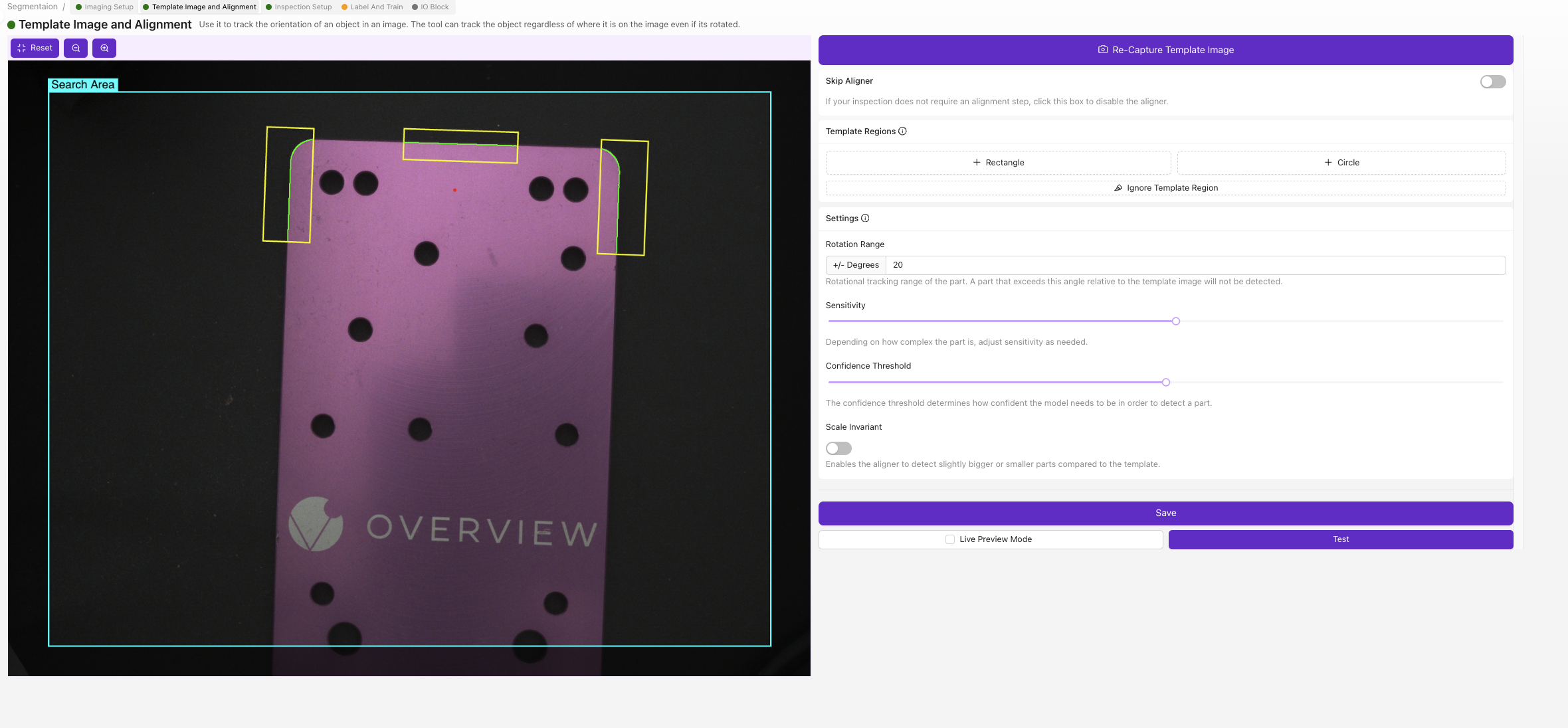

Step 4: Set Up Template and Alignment

4.1 Navigate to Template Section

Click "Template Image and Alignment" in breadcrumb menu

4.2 Configure Alignment (Optional)

![]()

For this example, we'll skip alignment:

- Select

Skip Alignerif parts are consistently positioned - Click

Save

When to Use Aligner: Enable when parts arrive in varying positions or orientations that would affect segmentation accuracy.

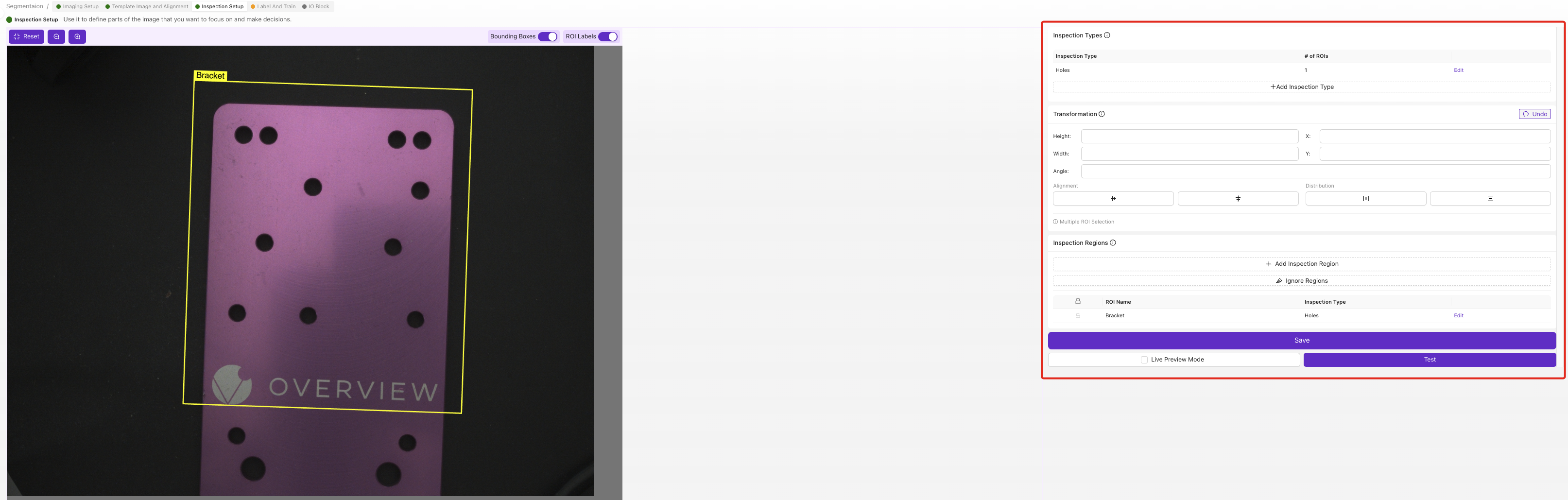

Step 5: Define Inspection Region

5.1 Navigate to Inspection Setup

Click "Inspection Setup" in breadcrumb menu

5.2 Set Region of Interest (ROI)

The ROI defines where segmentation will occur:

- Position a test part in camera view

- Drag ROI corners to frame the inspection area

- Size ROI appropriately:

- Include all areas where features might appear

- Exclude unnecessary background regions

- Leave small buffer around expected feature locations

5.3 ROI Best Practices for Segmentation

| Do | Don't |

|---|---|

| Cover entire inspection surface | Include irrelevant background objects |

| Leave buffer space around edges | Make ROI too small for feature variation |

| Consider part positioning variation | Overlap with fixtures or tooling |

| Test with largest expected features | Include areas with permanent markings |

5.4 Save ROI Settings

- Verify ROI covers all target areas

- Click

Save

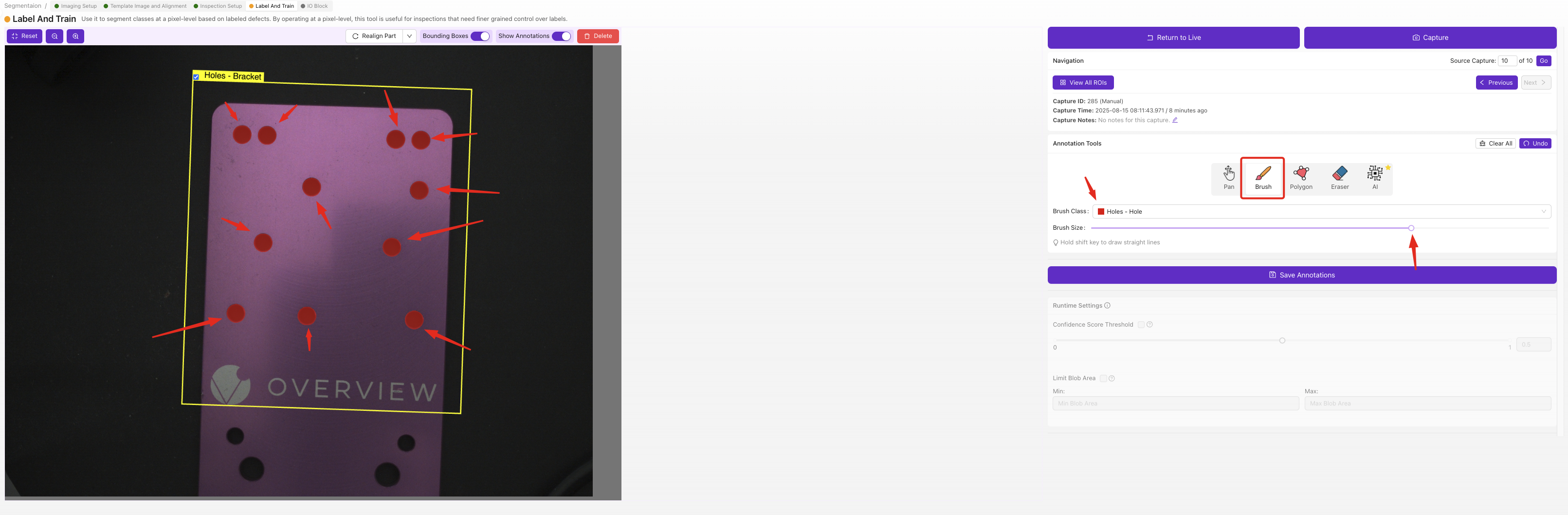

Step 6: Label Training Data

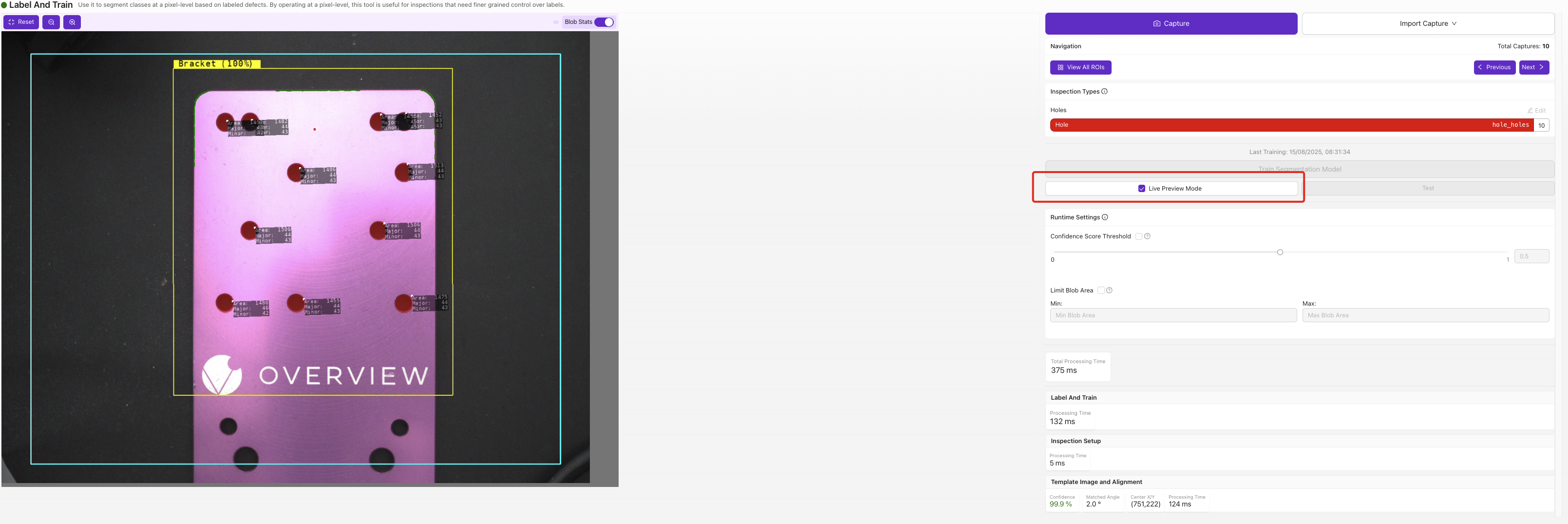

6.1 Navigate to Label And Train

Click "Label And Train" in breadcrumb menu

6.2 Configure Inspection Class

- Click

Editunder Inspection Types - Rename class to match your feature (e.g., "Pencil Mark", "Surface Defect", "Spill Area")

- Choose class color for visual identification

- Save changes

6.3 Capture and Label Training Images

You need minimum 10 labeled images, but 15-20 is recommended:

Image Capture Process

- Place first test part in inspection area

- Take image using camera interface

- Use Brush tool to paint over target features

- Paint accurately:

- Cover entire feature area

- Stay within feature boundaries

- Don't paint background areas

- Use consistent labeling approach

- Click

Save Annotations - Repeat with next part

Labeling Best Practices

| Good Labeling | Poor Labeling |

|---|---|

| Precise feature boundaries | Sloppy edge painting |

| Consistent feature definition | Inconsistent criteria |

| Complete feature coverage | Missing feature areas |

| Clean background (unpainted) | Accidental background painting |

6.4 Training Data Variety

Ensure your training set includes:

- Different feature sizes

- Various feature intensities

- Multiple locations within ROI

- Different lighting conditions (if applicable)

- Edge cases and borderline examples

6.5 Quality Check Training Data

- Review all labeled images

- Verify consistent labeling approach

- Remove any incorrectly labeled examples

- Add more examples if needed

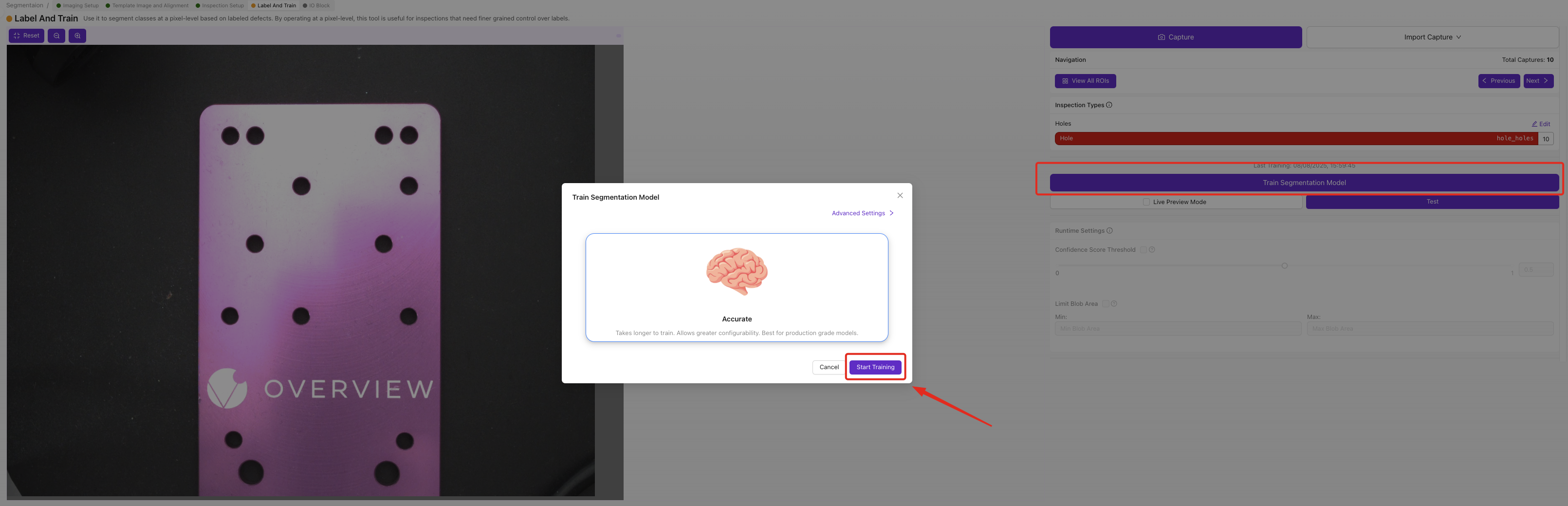

Step 7: Train Segmentation Model

7.1 Start Training Process

- Click

Return to Livewhen labeling is complete - Click

Train Segmentation Model

7.2 Configure Training Parameters

- Set Number of Iterations:

- Fast training: 50-100 iterations (5-10 minutes)

- Production quality: 200-500 iterations (15-30 minutes)

- High precision: 500+ iterations (30+ minutes)

- Click

Start Training

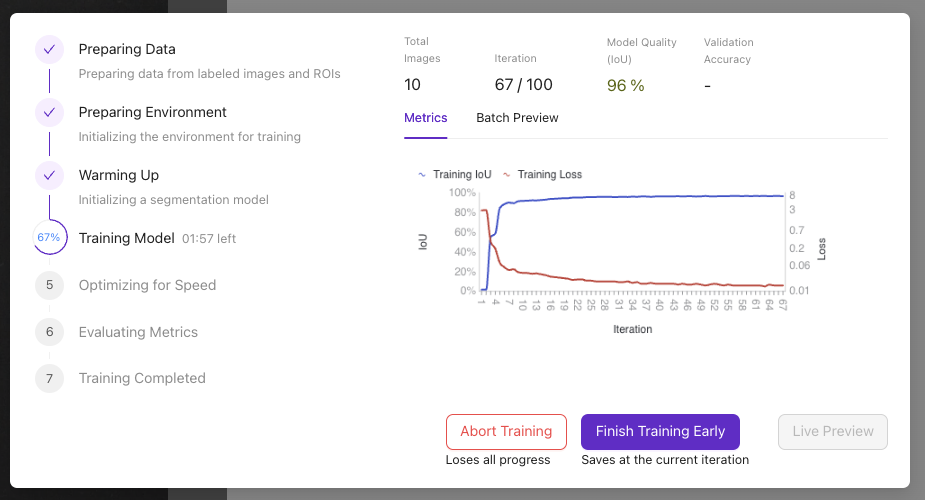

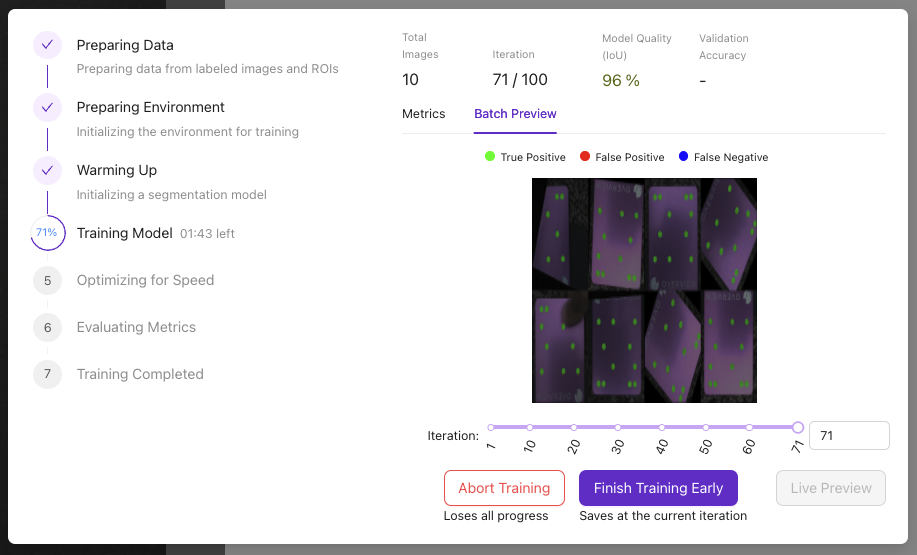

7.3 Monitor Training Progress

Training progress shows:

- Current iteration number

- Training accuracy percentage

- Estimated completion time

Training Controls:

- Abort Training: Stop if issues arise

- Finish Training Early: Stop when accuracy is sufficient

- 85% accuracy typically good for production

- Training automatically stops at target accuracy

- More training data often better than more iterations

Step 8: Test Segmentation Performance

8.1 Access Live Preview

- Click

Live Previewafter training completes - Test with various parts:

- Known good parts (should show no/minimal segmentation)

- Known defective parts (should highlight defects)

- Edge cases and borderline examples

8.2 Evaluate Results

Check segmentation quality:

| Metric | Good Performance | Needs Improvement |

|---|---|---|

| Accuracy | Finds real features consistently | Misses obvious features |

| Precision | Few false positives | Many background areas highlighted |

| Edge Quality | Clean, accurate boundaries | Rough or inaccurate edges |

| Consistency | Similar results on repeat tests | Highly variable results |

8.3 Troubleshooting Poor Results

| Problem | Likely Cause | Solution |

|---|---|---|

| Missing features | Insufficient training data | Add more labeled examples |

| False positives | Poor lighting/contrast | Improve imaging settings |

| Rough edges | Poor image quality | Improve focus/lighting |

| Inconsistent results | Inadequate training variety | Add more diverse examples |

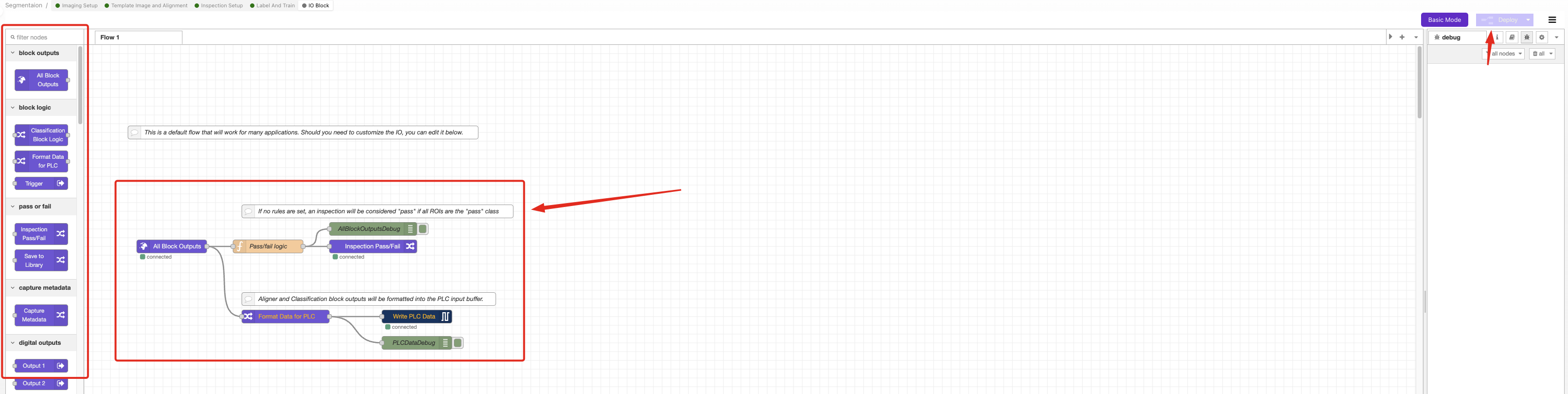

Step 9: Configure Pass/Fail Logic

9.1 Access IO Block

- Ensure AI model shows green (trained status)

- Navigate to IO Block via breadcrumb menu

9.2 Remove Default Logic

- Delete Classification Block Logic node

- Prepare to build custom segmentation logic

9.3 Build Segmentation Flow

Create Node-RED flow with these components:

- Drag nodes from left panel:

- Function node (for logic)

- Debug node (for testing)

- Final Pass/Fail node

- Connect nodes with wires

9.4 Configure Logic Based on Your Needs

Option A: Pass if No Defects Detected

Use Case: Quality inspection where any detected feature is a fail

Function Node Code:

const allBlobs = msg.payload.segmentation.blobs;

const results = allBlobs.length < 1; // Pass if no features found

msg.payload = results;

return msg;

Option B: Pass if Small Defects Only

Use Case: Accept minor defects below size threshold

Function Node Code:

const threshold = 500; // Adjust pixel count threshold

const allBlobs = msg.payload.segmentation.blobs;

const allUnderThreshold = allBlobs.every(blob => blob.pixel_count < threshold);

msg.payload = allUnderThreshold;

return msg;

Option C: Pass if Total Defect Area is Small

Use Case: Accept parts with limited total defect area

Function Node Code:

const threshold = 5000; // Adjust total pixel threshold

const allBlobs = msg.payload.segmentation.blobs;

const totalArea = allBlobs.reduce((sum, blob) => sum + blob.pixel_count, 0);

msg.payload = totalArea < threshold;

return msg;

9.5 Configure Function Node

- Double-click Function node

- Copy appropriate code from examples above

- Paste into "On Message" tab

- Adjust threshold values for your application

- Click

Done

9.6 Deploy and Test Logic

- Click

Deployto activate logic - Navigate to HMI for testing

- Test with known good and bad parts

- Verify pass/fail results match expectations

Step 10: Production Validation

10.1 Comprehensive Testing

Test segmentation system with:

| Test Case | Expected Result | Action if Failed |

|---|---|---|

| Clean parts | Pass (no segmentation) | Adjust thresholds or retrain |

| Minor defects | Pass/Fail per your criteria | Refine logic parameters |

| Major defects | Fail (clear segmentation) | Check model accuracy |

| Edge cases | Consistent behavior | Add training data |

10.2 Performance Validation

Monitor these metrics:

- Processing time per inspection

- Consistency across multiple tests

- Accuracy with production lighting

- Reliability over extended operation

10.3 Final Adjustments

If performance isn't satisfactory:

- Add more training data for edge cases

- Adjust threshold values in logic

- Improve imaging conditions

- Retrain model with additional iterations

Success! Your Segmentation System is Ready

You now have a working segmentation system that can:

- Automatically detect specific features or defects

- Measure areas with pixel-level precision

- Apply custom pass/fail logic based on your requirements

- Integrate with production systems via I/O controls

Advanced Configuration Options

Custom Threshold Logic

For complex acceptance criteria, combine multiple conditions:

const smallThreshold = 200;

const largeThreshold = 1000;

const maxTotalArea = 3000;

const allBlobs = msg.payload.segmentation.blobs;

const smallBlobs = allBlobs.filter(blob => blob.pixel_count < smallThreshold);

const largeBlobs = allBlobs.filter(blob => blob.pixel_count > largeThreshold);

const totalArea = allBlobs.reduce((sum, blob) => sum + blob.pixel_c