Set Digital Output Logic

This guide shows you how to configure the OV80i's digital outputs to control external devices based on inspection results. The camera has 2 digital outputs that operate with True/False logic to trigger sorting mechanisms, indicator lights, alarms, or other automation equipment.

When to Use Digital Outputs: Automated sorting systems, pass/fail indicator lights, reject mechanisms, alarm systems, PLC communication, or any external device that needs to be triggered based on inspection results.

Prerequisites

- OV80i camera system set up and connected

- Active recipe with inspection logic configured

- External device to control (optional for testing)

- Basic understanding of digital I/O concepts

Digital Output Specifications

The OV80i provides 2 digital outputs accessible via the M12 connector:

| Output | Pin # | Wire Color | Function |

|---|---|---|---|

| Digital Output 0 | 11 | Configurable output | |

| Digital Output 1 | 12 | Configurable output |

Operating Logic:

- True = Output ON (24V)

- False = Output OFF (0V)

Step 1: Access Node-RED Editor

1.1 Navigate to IO Block

- Open your active recipe in Recipe Editor

- Click "IO Block" in breadcrumb menu

- Click "Configure IO" to enter Node-RED editor

1.2 Verify Node-RED Interface

Checkpoint: You should see the Node-RED flow editor with the node palette on the left side.

Step 2: Add Digital Output Node

2.1 Locate Output Node

- Find "Output" node in the left panel (Overview section)

- Drag "Output" node onto the flow canvas

- Double-click node to configure

2.2 Configure Output Settings

Node Configuration:

| Setting | Options | Description |

|---|---|---|

| Output Pin | DO0, DO1 | Select which physical output to control |

| Initial State | OFF, ON | Starting state when system boots |

| Name | Custom text | Optional label for identification |

2.3 Output Configuration Steps

- Select Output Pin:

- DO0 = Digital Output 1 (Pin 11)

- DO1 = Digital Output 2 (Pin 12)

- Set Initial State:

- OFF = Output starts in OFF state (recommended)

- ON = Output starts in ON state

- Name the Node:

- Use descriptive names like "Reject_Signal" or "Pass_Light"

- Click "Done" to save configuration

Step 3: Connect Logic to Output

3.1 Basic Pass/Fail Output

For simple pass/fail indication:

- Add "Final Pass/Fail Output" node (if not already present)

- Connect: Final Pass/Fail → Output Node

- Result: Output activates when inspection passes

3.2 Inverted Logic (Fail Signal)

To trigger output on inspection failure:

- Add "function" node between pass/fail and output

- Configure function node:

// Invert pass/fail signal - ensure boolean output

msg.payload = !msg.payload;

return msg;

- Connect: Final Pass/Fail → Function → Output Node

- Result: Output activates when inspection fails

3.3 Custom Logic from Classification Results

When using classification or other inspection data:

- Add "function" node to convert results to boolean

- Configure function for your logic:

// Convert classification result to boolean

// Example: Activate output for specific class

if (msg.payload.class === "Defective") {

msg.payload = true; // Turn output ON

} else {

msg.payload = false; // Turn output OFF

}

return msg;

- Connect: Data Source → Function → Output Node

3.4 Boolean Conversion Examples

For different data sources, always convert to boolean:

From confidence values:

// Activate if confidence below threshold

msg.payload = (msg.payload.confidence < 0.8);

return msg;

From ROI results:

// Activate if any ROI failed

msg.payload = msg.payload.roi_results.some(roi => !roi.pass);

return msg;

The Output node requires boolean input (true/false). Always ensure your logic produces boolean values before connecting to the Output node.

Step 4: Create Pulse Output (Recommended)

4.1 Why Use Pulse Output

Pulse output is recommended because:

- Provides clear signal indication

- Prevents output from staying ON indefinitely

- Better for triggering external equipment

- Easier to troubleshoot signal timing

4.2 Add Trigger Node

- Add "trigger" node from Function section

- Place between logic source and output node

- Double-click trigger node to configure

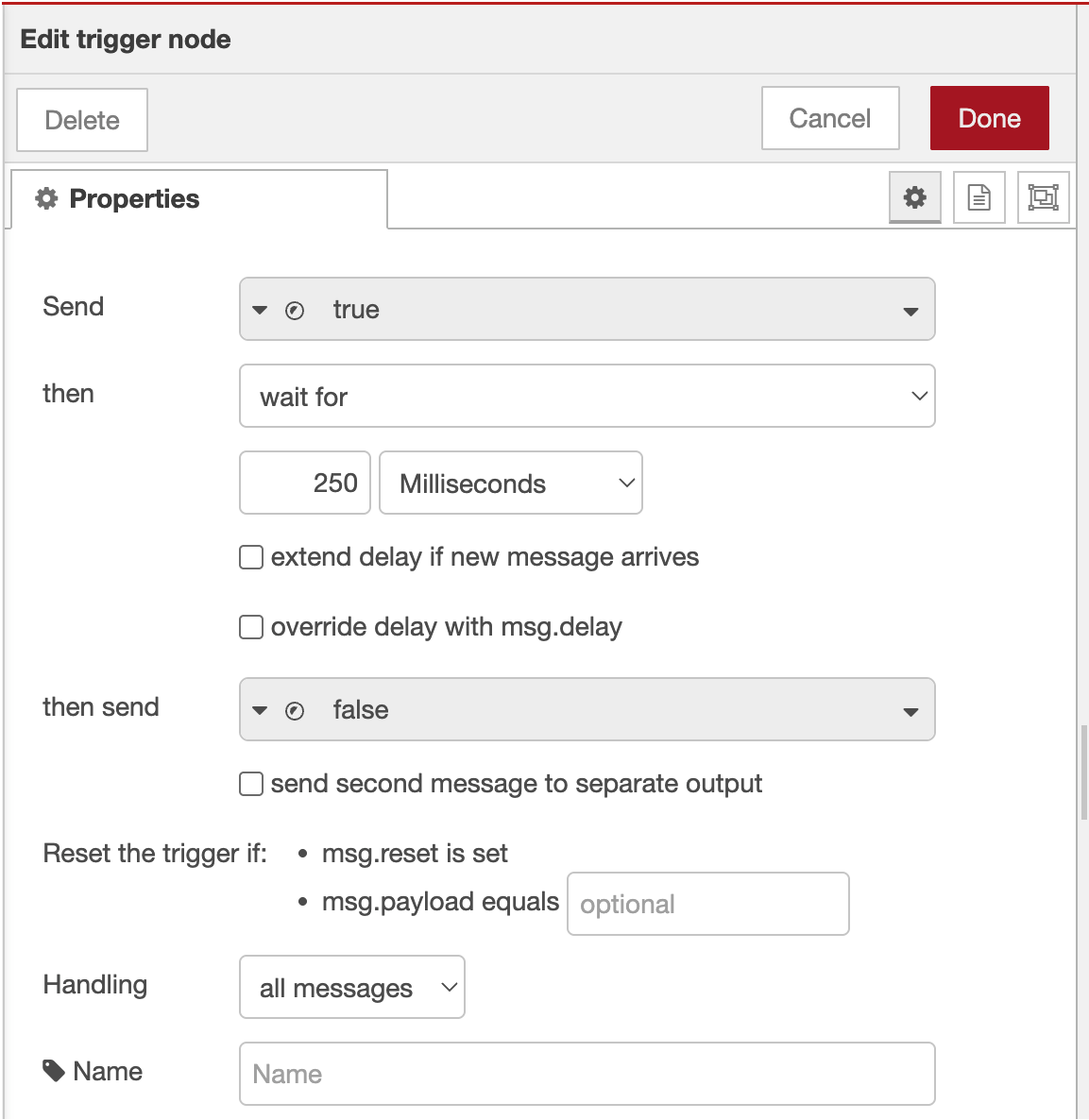

4.3 Configure Trigger Settings

Pulse Configuration:

| Setting | Recommended Value | Description |

|---|---|---|

| Send | True | Initial signal to send |

| Then wait | 500ms | Pulse duration |

| Then send | False | Signal after delay |

| Extend delay | Disabled | Don't extend on new messages |

4.4 Trigger Configuration Steps

- First Output:

- Send:

boolean→true - This turns the output ON

- Send:

- Delay Settings:

- Then wait for:

500milliseconds - Then send:

boolean→false - This turns the output OFF after delay

- Then wait for:

- Advanced Options:

- Extend delay if new message arrives: Unchecked

- Stop existing delay if new message arrives: Checked

- Click "Done" to save

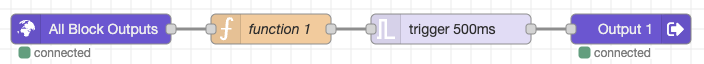

4.5 Wire Pulse Configuration

Connect nodes in this order: Logic Source → Trigger → Output Node

Example flow: Final Pass/Fail → Trigger → Output (DO0)

Step 5: Deploy and Test Configuration

5.1 Deploy Flow

- Click "Deploy" button (top-right corner)

- Verify deployment success message

- Check node status indicators

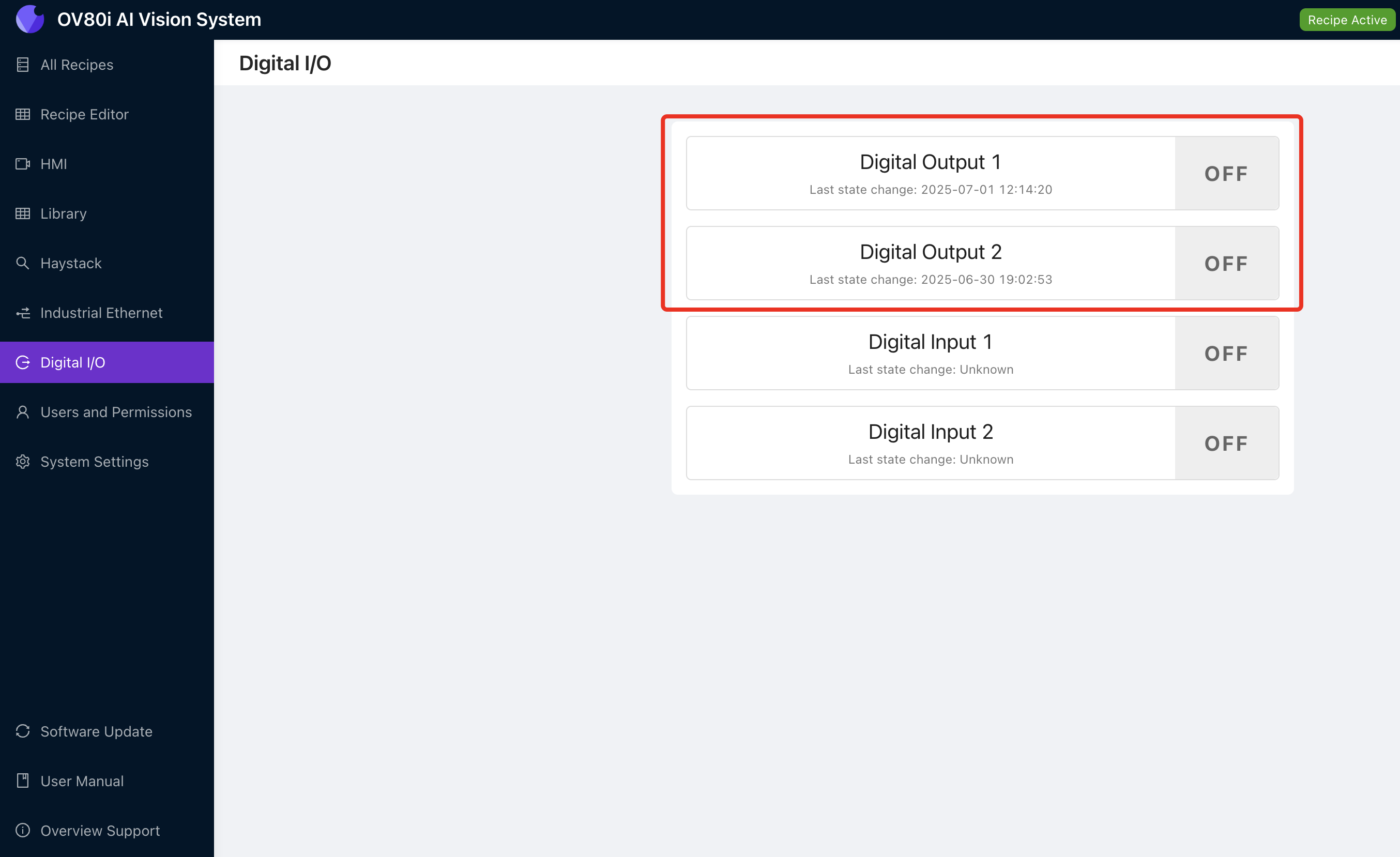

5.2 Monitor Digital I/O Status

Use the built-in I/O monitoring screen:

- Navigate to "Digital I/O" page in main interface

- Observe output status in real-time

- Check "Last state change" timestamps

I/O Status Screen shows:

- Current output state (ON/OFF)

- Last state change timestamp

- Real-time status updates

![Digital I/O Status Screen - Insert your I/O monitoring interface screenshot here showing Digital Output 1 and Digital Output 2 status with timestamps]

5.3 Test Output Activation

Manual Testing:

- Add "inject" node for testing

- Configure inject node:

- Payload:

boolean→true - Name: "Test Output"

- Payload:

- Connect: Inject → Trigger → Output

- Click inject button to test output

- Verify output activation in I/O status screen

Step 6: Advanced Output Configurations

6.1 Multiple Output Control

Control both outputs simultaneously:

- Add separate output nodes for DO0 and DO1

- Connect same logic source to both outputs

- Use different trigger delays if needed

6.2 Conditional Output Selection

Route to different outputs based on conditions:

- Add "switch" node from Function section

- Configure routing rules:

// Route based on classification result

if (msg.payload.class === "Large") {

return [msg, null]; // Send to first output (DO0)

} else if (msg.payload.class === "Small") {

return [null, msg]; // Send to second output (DO1)

}

return [null, null]; // No output

- Connect switch outputs to respective output nodes

6.3 Delayed Output Sequences

Create timed output sequences:

- Add multiple trigger nodes with different delays

- Configure sequence timing:

- First trigger: 100ms pulse

- Second trigger: 500ms delay, then 200ms pulse

- Connect in series for sequential activation

Step 7: Integration Examples

7.1 Sorting System Integration

Two-way sorting setup:

- DO0 (Output 1): Good parts conveyor

- DO1 (Output 2): Reject bin actuator

Final Pass/Fail → Switch Node → Trigger → DO0 (Pass)

→ Trigger → DO1 (Fail)

7.2 Alarm System Integration

Multi-level alarm system:

- DO0: Warning light (minor defects)

- DO1: Alarm horn (major defects)

Classification Logic → Function (Check severity) → Appropriate Output

7.3 PLC Communication

Simple PLC handshake:

- DO0: Inspection complete signal

- DO1: Part reject signal

All Block Outputs → Format for PLC → Trigger → DO0

→ Reject Logic → Trigger → DO1

Step 8: Troubleshooting Output Issues

8.1 Output Not Activating

| Problem | Check | Solution |

|---|---|---|

| No output signal | Node connections | Verify all wires are connected |

| Logic never triggers | Input conditions | Check pass/fail logic configuration |

| Timing issues | Trigger settings | Adjust pulse duration |

| Wrong pin active | Output pin selection | Verify DO0/DO1 configuration |

8.2 Using I/O Status for Troubleshooting

The Digital I/O screen helps identify:

- Current Output State: See if output is actually changing

- Last State Change: Verify timing of output activation

- State History: Track output behavior over time

Troubleshooting with I/O Screen:

- Output shows "OFF" always: Logic may not be triggering

- Output shows "ON" always: Missing pulse configuration

- No timestamp updates: Check Node-RED connections

- Rapid state changes: Logic may be triggering too frequently

8.3 External Device Issues

| Problem | Cause | Solution |

|---|---|---|

| Device doesn't respond | Voltage mismatch | Verify 24V compatibility |

| Intermittent operation | Wiring issues | Check M12 connector wiring |

| Delayed response | External device timing | Adjust pulse duration |

Step 9: Testing and Validation

9.1 Systematic Testing

Test each output systematically:

| Test | Expected Result | Status |

|---|---|---|

| Manual trigger DO0 | Output 1 activates for pulse duration | ☐ |

| Manual trigger DO1 | Output 2 activates for pulse duration | ☐ |

| Pass condition | Correct output activates | ☐ |

| Fail condition | Correct output activates | ☐ |

| I/O status updates | Timestamps show state changes | ☐ |

9.2 Production Validation

Before deploying to production:

- Test with actual parts and inspection conditions

- Verify output timing meets external device requirements

- Confirm electrical connections are secure

- Document output assignments for maintenance

9.3 Performance Verification

Monitor these aspects:

- Response time: Output activation delay after inspection

- Reliability: Consistent output behavior over time

- Timing accuracy: Pulse duration matches configuration

Success! Your Digital Outputs are Ready

Your digital output system can now:

- Control external devices based on inspection results

- Provide pulse signals for reliable triggering

- Support multiple output configurations for complex automation

- Integrate with PLCs and sorting systems for production automation

- Monitor output status through the built-in I/O interface

Ongoing Maintenance

Regular System Checks

- Monitor I/O status screen for consistent operation

- Verify output timing remains within specifications

- Check electrical connections at M12 connector

- Test manual triggers periodically to ensure system health

Troubleshooting Resources

- Use I/O status screen for real-time diagnostics

- Check Node-RED debug panel for logic issues

- Verify external device specifications match output capabilities

- Document any configuration changes for future reference

Next Steps

After configuring digital outputs:

- Set up digital input triggers if needed for external control

- Configure PLC communication for integrated automation

- Implement safety interlocks for production environments

- Create automated monitoring for system health